Bonding wires are essential for the quality and performance of underglow LED strips. Probably you may not have known that they have a significant impact on the lifespan of LED strips. Then keep reading and we will explain why.

1. What are bonding wires?

In plain English

bonding wires are the 5 very small wires – as small as hair – that you can see on the top of DITRIO’s SMD RGB 5050 LEDs. They are so tiny that you may not have noticed them unless you observe carefully or use a magnifier.

When you light the LEDs up with the minimum brightness, you will see some spots give out light. It is the bonding wires connecting those spots to function properly.

Technical bits

Now let us explain using some scientific terms. The bonding wires on SMD LEDs transmit power and signal between substrates and chips – so they can give out light and know what colors to display.

They are critical to interconnect die-to-substrate in LED packaging. Bonding wires also help dissipate heat when LEDs are working.

2. Types of bonding wires

The 4 Common Types

Generally speaking, there are at least 4 types of bonding wires for LEDs in the market. They are gold wires, silver wires, copper wires, and alloy wires.

It is important to notice their differences, and one useful method is to look at the appearance of the bonding wires. The gold and copper bonding wires appear to be a little bit yellowish, while the silver and alloy wires may appear to be grey or white.

Not created the same

The cost of each type of bonding wire can be quite different, so LEDs of the same model – for example, the SMD RGB 5050 – can have a big difference, even a double price.

Therefore, if you only check the models and prices of different LEDs to compare, it won’t be logical to draw a conclusion on the false assumption that the LEDs themselves are the same.

- LEDs with cheaper bonding wires may only last for several months. Then you will begin to see colors shift, decreased brightness and some LEDs no longer come on.

- However, LEDs with better quality can last for double, or triple the time and even longer. You won’t see those typical issues with the cheaper LEDs.

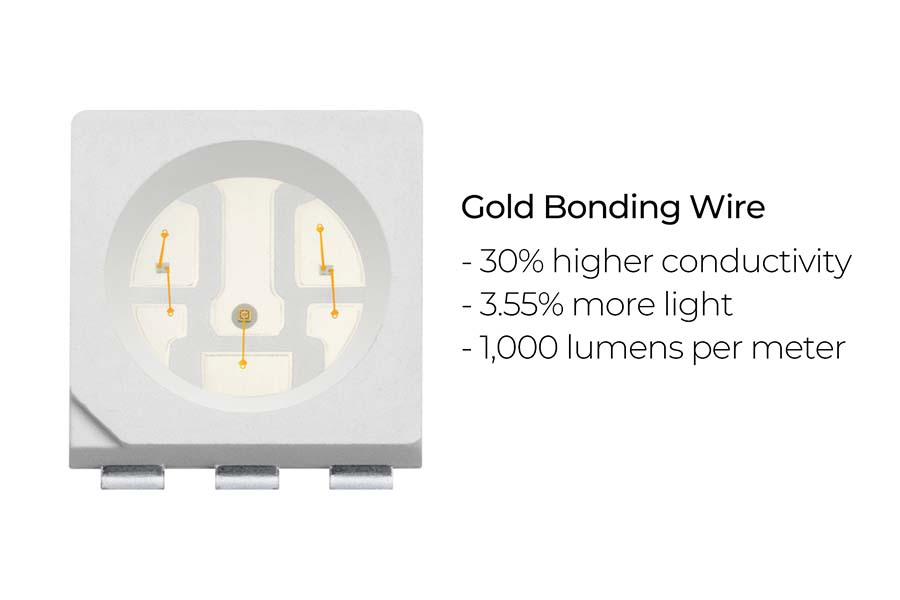

3. Features of gold bonding wires

Gold bonding wires are the top-quality among various types of wires for SMD RGB LEDs. Their most important feature is reliable performance in the long term.

Below are some technical bits about gold bonding wires.

- The thermal conductivity of gold is 317W/mK and it lasts much longer as it will not oxidize easily.

- Gold also has an electrical conductivity 30% higher than copper.

- Under the same experimental conditional LED encapsulations using gold bonding wire produced 3.55% more light (lumen) than those encapsulated with copper.

There are at least 3 important technical features for gold bonding wires.

1). Lower temperatures

Excessive heat is very negative for the life span of LED strips. As their temperature increases, the estimated life span will decrease dramatically.

We’ve checked the temperatures of LED strips using an infrared thermometer. And measured the temperatures on the top of LEDs under the same conditions:

- DC 15V (Approximately the maximum voltage of motorcycle batteries after fully charged)

- All LEDs in white colors at their maximum brightness

The result that we got:

- Generally, the LEDs with alloy wires are at least 10 °C (50 °F) than those with gold bonding wires.

- There is a rough approximation: a 10°C increase in temperature reduces the life of electronics by half.

This is not quite an accurate estimation, and it’d be beyond our scope to study in a scientific way, but it does imply that the operating temperatures can very much affect electronics reliability.

2). Consistent performance

Probably you may notice the colors of LED strips are different months after they are installed, or their brightness appears to decrease to a certain extent that is noticeable by the naked eye. One major cause for such quality issues is their bonding wires are made from cheaper alloy bonding wires.

Meanwhile, LEDs with gold bonding wires can consistently provide performance that seems to remain unchanged for over 2 years, particularly for some applications with optimum working environments.

3). Less battery consumption

Generally speaking, the gold bonding wires are more conductive with a smaller resistance. That means, they will use less battery to provide the same brightness as that of the LEDs with alloy bonding wires.

This can be a useful feature if you install 18 or even more underglow LED strips on your bike, particularly, if you’d like to keep the strips on after turning off the bike’s engine.

Above are some of the essential points regarding bonding wires and gold bonding wires for underglow SMD LEDs. Hope they are helpful for you to evaluate different strip kits.

Coupon Code:

If you happen to be looking for underglow LED strip kits for your motorcycle, you can consider buying from DITRIO. We only use LEDs with gold bonding wires. And we are more than happy to offer a code with 5% off: DMULK5